GYRATORY COMPACTOR

Category: ASPHALT-PREMIX, BITUMEN

SKU: ASPHALT - PREMIX

Product Info

- Description

- Specification

ASPHALT-PREMIX

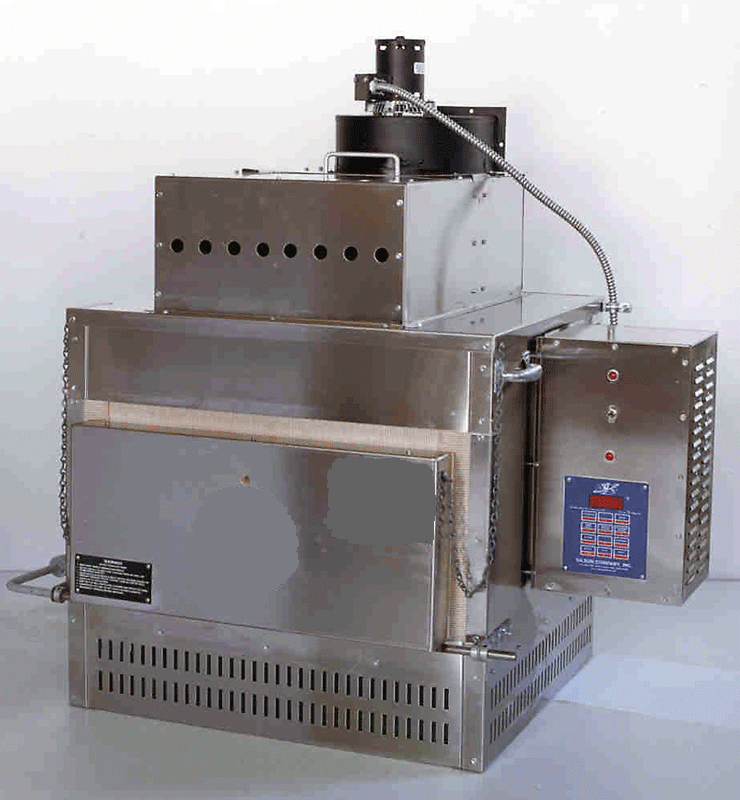

GYRATORY COMPACTOR TM 19

EN 12697-10 EN 12697-31 ASTM D 6307 SHRP M 02

Approved by the south Central Super pave Center- "comparable

12 out of 12 times, a perfect rate of comparison".

The Gyratory Compactor, which produces consistent replication

of the testing environment from test to test, includes a Pentium-

based PC, calibration equipment and software at no additional

cost. The compaction chamber is completely enclosed.

Continuous height measurement of the specimen during

compaction to within +- 0.1 mm.

Built-in power-assisted specimen extractor means no hand

pumping. Work area which allows user to charge the mold,

compact the specimen and extract it without lifting the mold.

Real-time display of data. User-friendly software programs for

editing, test data acquisition and analyzing test data. See-through

door and illuminated chamber allow continuous observation of

compaction cycle.

Safety switch which stops gyration when guard door is open.

Emergency stop button. Quick, easy mold alignment.

100 mm and 150 mm molds are accepted.

Complete with 150 mm Gyratory Mold, 150 mm Mold Bottom.

150 mm Piston Face, IBM compatible computer pre-loaded

with Windows operating system. Gyratory Software, Gyratory

Calibration Device, and 150 mm dia. paper Disc (N'500).

Specifications:

Consolidation Pressure: Preset from 200 kPa to 1,000 kPa +/- 3% throughout test.

Minimum height of sample: 40 mm.

Ram Travel Speed: adjustable, factory setting: 10 mm per second

Angle of Gyration: adjustable from 0.5° to 2.0°, ±0.2° (factory setting: 1.25°)

Gyratory cycle: 0-999. Height of specimen continuously

measured during test to within : ±0.1 mm accuracy

Rate of Gyration: 30.0 rpm +/-0.5 rpm, constant

Automated Shutoff: Preset specimen height, Nmax,or numbered of gyrations.

Mold Construction: steel, minimum Rockwell hardness of C 48:

inside surface finish of 1.6 um

Communications: RS-232 port. Mold Height: 250 mm. Mold Wall

Thickness: 9.5 mm minimum.

POWER SUPPLY: 220 V, 50 Hz, single phase, 3500 W

DIMENSIONS: 536 X 711 X 1600 (h) mm.

MACHINE WEIGHT: 250 kg.

PACKED WEIGHT: 440 kg.

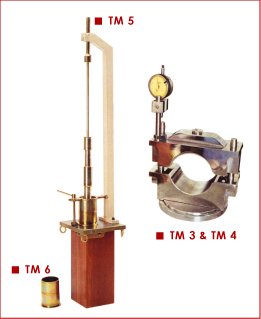

ACCESSORIES AND SPARE PARTS:

TM 19-01 150 mm diameter mould

TM 19-02 Base plate for B 100/1

TM 19-03 Upper plate for B 100/1

TM 19-04 Filter paper diameter 150 mm (500 pieces)

TM 19-05 100 mm diameter mould

TM 19-06 Base plate for B 100/2

TM 19-07 Upper plate for B 100/2

TM 19-08 Filter paper diameter 100 mm (500 pieces)

TM 19-09 Perforated plate diameter 150 mm

TM 19-10 Shear strength measurement equipment

Only available for 150 mm diameter moulds